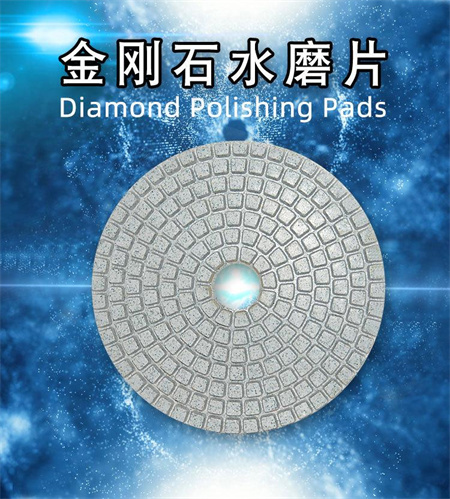

If you’re in the market for high-quality polishing pads, you’ve come to the right place. As a leading China OEM polishing pad manufacturer, we pride ourselves on delivering bulk supplies that meet the unique needs of every customer. Whether you’re in the automotive, industrial, or consumer goods sector, our polishing pads are designed to enhance your polishing and finishing processes, ensuring top-notch results every time.

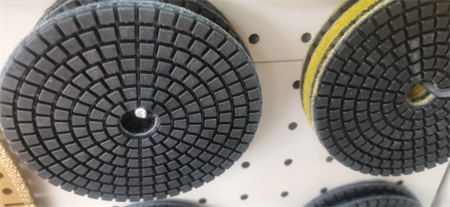

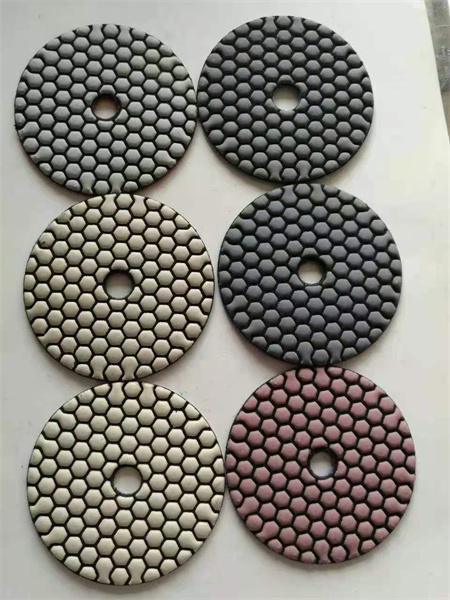

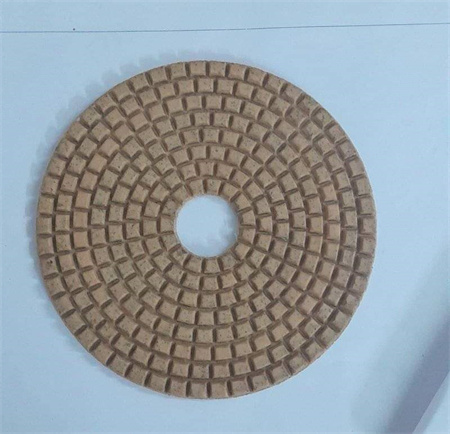

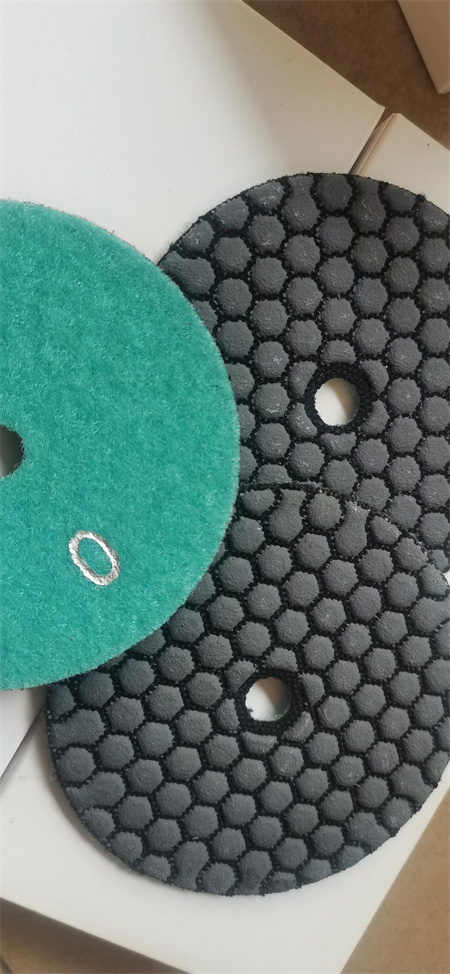

Our commitment to quality is reflected in every product we manufacture. We use advanced materials and cutting-edge technology to craft pads that offer durability, consistency, and excellent performance. Whether you’re polishing delicate surfaces or tackling tougher materials, our pads are up to the task, providing smooth, even results without leaving any unwanted marks or scratches.

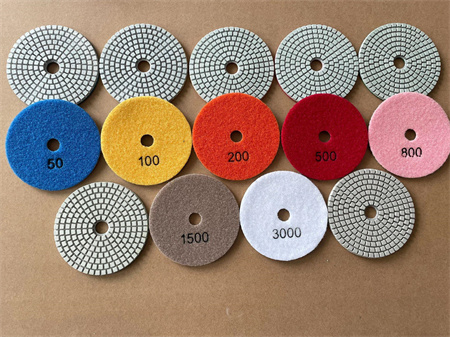

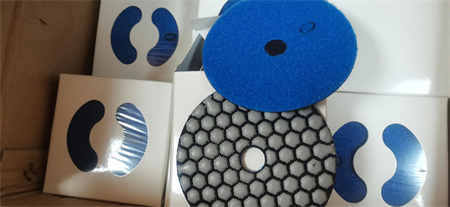

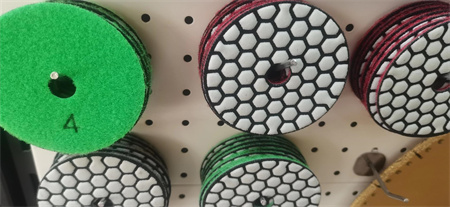

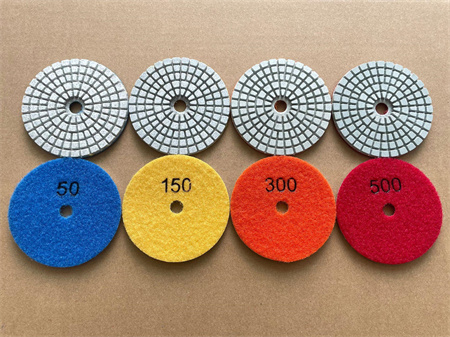

As an OEM manufacturer, we understand the importance of customization. That’s why we offer a range of sizes, colors, and thicknesses to cater to diverse industry needs. Our pads can be tailored to suit specific requirements, whether you need them for floor polishing, car detailing, or any other specialized use. By working directly with us, you gain access to affordable bulk supplies without compromising on quality.

Sourcing polishing pads from a reliable manufacturer can make a world of difference in your operations. With years of experience in the industry, we’ve built a reputation for providing efficient, effective, and eco-friendly solutions. Our products are tested under rigorous conditions to ensure that they stand up to the most demanding tasks. Plus, we offer excellent customer service, providing support and guidance to help you choose the right product for your needs.

Choosing us as your supplier means you’re not only getting a product that performs well, but also one that’s backed by a team of experts who are dedicated to your satisfaction. So, if you’re looking for reliable, affordable, and high-performance polishing pads, trust us to deliver. Let’s elevate your polishing game with products that work as hard as you do.