When it comes to polishing concrete, granite, marble, or other stone surfaces, the type of polishing pad you choose can make a huge difference in both performance and cost. Resin bond and metal bond diamond polishing pads are two of the most common options, each offering distinct benefits and price points. Let’s dive into the differences and explore the cost-effectiveness of each.

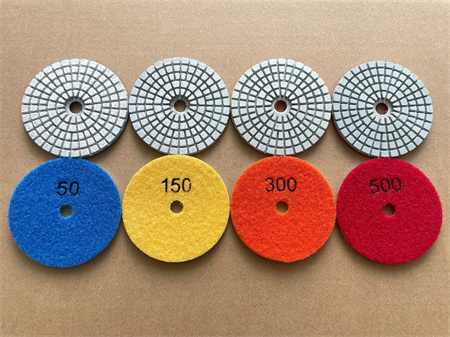

Resin bond pads are designed with a flexible resin material that holds the diamonds in place. These pads are perfect for fine finishing and polishing, as they provide a smooth, glossy finish. They work best on surfaces that have already been ground down and are looking for that final, high-sheen look. One of the key benefits of resin bond pads is that they’re softer, which allows them to contour better to the surface. This makes them ideal for polished concrete floors and stone surfaces that require a fine touch.

On the other hand, metal bond pads are typically used for rough grinding and initial surface preparation. The metal bonds are harder and more durable, which makes these pads perfect for aggressive grinding or removing thick layers of material. Metal bond pads also last longer compared to resin pads, especially when used on tougher surfaces like granite or marble. Their lifespan can significantly reduce the frequency of pad replacements, making them a great long-term investment.

When it comes to cost comparison, metal bond pads tend to have a higher upfront price. However, considering their durability and longer lifespan, the overall cost per square foot can often be more economical in the long run. Since metal bond pads are ideal for the rough stages of polishing, they also save time, which can lead to savings on labor costs.

Resin bond pads, while cheaper to purchase initially, may need to be replaced more frequently due to their softer nature. As a result, they might be more expensive over time, especially if you’re using them for extended periods on harder surfaces. But for high-polish finishes, the smoother results they provide may justify the additional cost of replacements.

In terms of performance, the choice between resin bond and metal bond pads boils down to the project’s needs. If you’re working on a smooth, fine finish, resin pads are the way to go. But if you need something durable that can handle rough grinding and last longer, metal bond pads are a solid choice. Ultimately, the decision comes down to balancing the cost against the longevity and the specific demands of your polishing job.

Whether you go for resin bond or metal bond, knowing the strengths and costs of each will help you make an informed decision that fits both your budget and your project’s needs.