How Technology Is Changing the Diamond Polishing Tool Market

The diamond polishing tool market is undergoing a dramatic transformation, driven largely by the rapid advancements in technology. These tools, essential for achieving the high levels of precision and smoothness needed in industries ranging from jewelry to electronics, are becoming more efficient, precise, and cost-effective due to these technological breakthroughs. In a world where perfection and efficiency are highly prized, the role of technology in shaping this market is becoming increasingly evident.

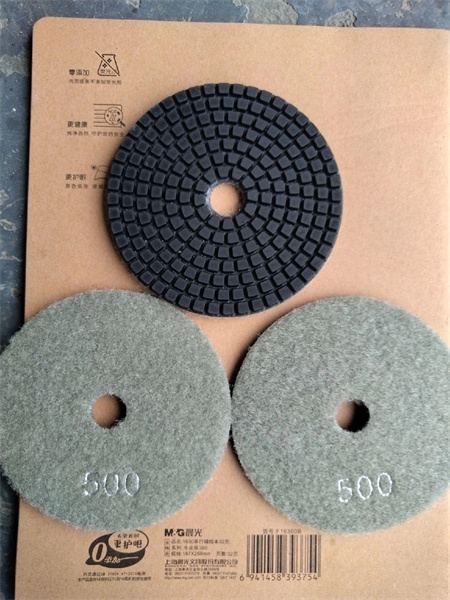

Historically, diamond polishing was a slow, labor-intensive process. It required skilled craftsmen to manually handle the delicate material, carefully grinding and polishing each stone to achieve the desired finish. While the process is still a highly specialized art, technology is now playing a vital role in automating and enhancing many aspects of diamond polishing. From the introduction of high-speed diamond polishing machines to the development of advanced materials and coatings, these innovations are transforming the way diamonds are worked on.

One of the key ways technology is impacting the diamond polishing tool market is through automation. With the introduction of computer numerical control (CNC) machines, manufacturers can now achieve highly precise and repeatable results with less human intervention. These machines are capable of handling intricate and detailed work at a much faster rate than traditional hand-polishing methods. As a result, diamond polishing is not only becoming more efficient but also more consistent, ensuring a level of quality that was previously unattainable.

Laser technology is also making waves in the diamond polishing industry. Lasers can now be used to cut, shape, and polish diamonds with unparalleled precision. Unlike traditional methods, laser polishing allows for a higher degree of control and reduces the risk of damaging the delicate diamond. Moreover, laser systems can be integrated into existing machinery, providing manufacturers with an affordable way to upgrade their production processes. This capability has opened up new possibilities for the diamond polishing market, allowing for more complex designs and the polishing of even the most challenging diamond shapes.

In addition to automation and new tools, advances in artificial intelligence (AI) and machine learning are changing the way diamond polishing is approached. AI-driven systems are now capable of analyzing diamond surfaces with incredible accuracy, detecting imperfections and providing real-time feedback to operators. These systems can identify areas that need more attention, optimize polishing parameters, and even predict the outcome of a polishing session based on previous data. As these AI technologies continue to evolve, they are likely to become an integral part of diamond polishing operations, making the entire process smarter and more efficient.

Sustainability is also a key driver of technological change in the diamond polishing tool market. With increasing pressure on industries to reduce their environmental impact, manufacturers are exploring eco-friendly alternatives to traditional polishing methods. For example, water-based polishing agents and energy-efficient machines are being developed to reduce waste and energy consumption. These innovations not only benefit the environment but also help manufacturers reduce operating costs and improve the overall sustainability of their operations.

Looking forward, the future of the diamond polishing tool market is undoubtedly tied to the continued evolution of technology. As innovation accelerates, manufacturers will have access to even more advanced tools and methods that will make diamond polishing faster, more precise, and more sustainable. With automation, AI, laser technology, and 3D printing leading the charge, the industry is poised for even greater changes in the years to come.

In conclusion, technology is reshaping the diamond polishing tool market in profound ways. The combination of automation, advanced materials, AI, and sustainable practices is not only making diamond polishing more efficient but also opening up new possibilities for creativity and precision. As the industry continues to evolve, these technological advancements will ensure that the diamond polishing market remains at the forefront of innovation, offering solutions that meet the ever-increasing demands of consumers and industries worldwide.