Achieving a glossy finish on sandstone can elevate its natural beauty, enhancing its visual appeal and ensuring it stands out in any space, whether it’s an outdoor patio, indoor feature wall, or a decorative piece. Sandstone, with its soft, porous texture, can be a challenge to polish effectively. However, with the right tools and techniques, it’s possible to achieve a smooth, lustrous surface that showcases the stone’s unique patterns and colors.

One of the most effective ways to bring out a polished, glossy finish is by using diamond tools. These specialized tools are designed to work with the hardest surfaces and can provide a fine, smooth finish without damaging the stone. But achieving that sleek, reflective surface doesn’t happen overnight. It takes a combination of the right equipment, patience, and technique.

Start with the Right Diamond Tools

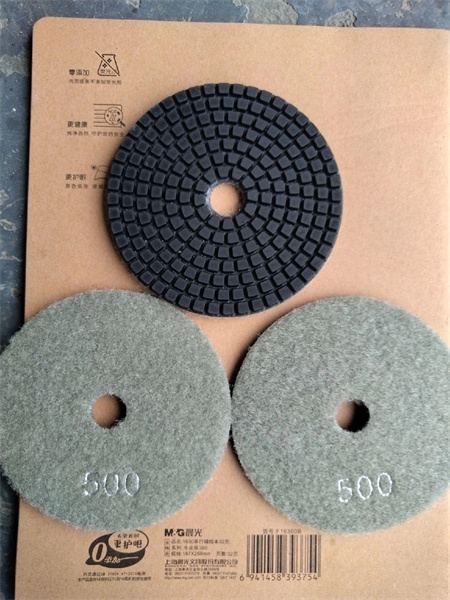

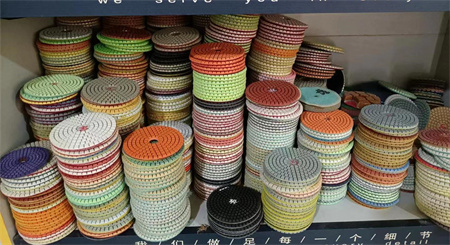

Diamond tools are essential when polishing sandstone. The durability of diamond abrasives allows for efficient cutting and smoothing of the stone’s surface. To begin, you’ll need a set of diamond grinding wheels or pads, which are available in various grits. The grit size will determine the roughness of the finish, so starting with a coarser grit is essential to remove any large imperfections or rough patches.

Diamond grinding wheels, typically mounted on a floor grinder or handheld machine, are ideal for the initial grinding phase. They help to level out any uneven surfaces, smooth out sharp edges, and prepare the stone for the finer polishing stages. Depending on the condition of the sandstone, you may want to start with a grit in the range of 30 to 50. Once you’ve ground down the surface to remove any roughness or scratches, you’ll be ready to move on to finer grits.

After the initial grinding, the key to achieving a glossy finish is to work your way through progressively finer grits. Start by switching to a medium grit, around 100 to 200, which will refine the surface further. At this stage, you’ll notice the roughness beginning to diminish, and the stone will begin to take on a smoother, more even appearance.

Next, move to a finer grit, such as 400 to 800, to bring out a more polished look. This finer grinding helps to eliminate any remaining scratches or swirl marks left from the previous grits. Polishing at this stage is crucial because it begins to reveal the inherent beauty of the sandstone’s texture and color.

Polishing for a Glossy Finish

Once the surface is smooth, you can begin the polishing process. This phase involves the use of diamond polishing pads, which are designed to buff the surface to a high shine. These pads come in various grits, with higher numbers providing a finer polish. For a glossy finish, you’ll want to use pads in the range of 1,500 to 3,000 grit.

When using diamond polishing pads, it’s important to keep the surface damp, as water helps reduce heat buildup and dust. As you work the pads over the sandstone, make sure to apply even pressure and allow the polishing pads to glide smoothly over the surface. Too much pressure can cause the pads to wear out too quickly or, worse, damage the stone. Take your time and let the polishing pads do the work.

The polish will start to develop slowly, but as you continue, you’ll notice the sandstone becoming shinier, revealing a stunning reflective finish. Keep in mind that patience is key. Rushing through the polishing process can result in an uneven or lackluster finish, so take your time to ensure each grit is worked thoroughly before moving on to the next.

Sealing the Surface

Make sure to choose a sealer designed specifically for natural stone, and follow the manufacturer’s instructions for application. Typically, you’ll apply a thin layer of sealer with a cloth or sponge, allowing it to absorb into the surface. After letting it sit for the recommended time, buff away any excess sealer to ensure an even coating.

Final Touches

Once the sealer has fully cured, step back and admire your work. The glossy finish on your sandstone should now reflect light beautifully, accentuating the stone’s natural colors and patterns. The polished surface will not only look more sophisticated but will also stand up better to wear and tear, maintaining its appearance for longer.