How to Achieve Perfect Symmetry in Stone Polishing

Achieving perfect symmetry in stone polishing is more than just a matter of technique; it’s about mastering the delicate balance between precision, patience, and the unique qualities of each stone. Whether you’re working with marble, granite, or any other stone, the end goal is always the same: a smooth, reflective surface that showcases the natural beauty of the material. But how do you reach that level of perfection?

The first thing to understand is that stone polishing is an intricate process that requires a deep understanding of both the material you’re working with and the tools at your disposal. Each type of stone reacts differently to polishing, and achieving symmetry involves careful attention to detail at every stage of the process.

The journey to perfect symmetry starts long before the polishing phase itself. It’s crucial to select a stone that has already been prepped properly. The stone should be cut to the right dimensions, with its surface free from any significant blemishes or irregularities. Inconsistent cuts or rough edges will make it nearly impossible to achieve symmetry, as the polishing process only accentuates these imperfections.

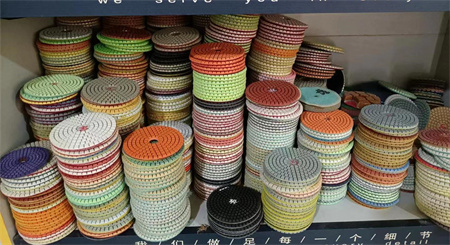

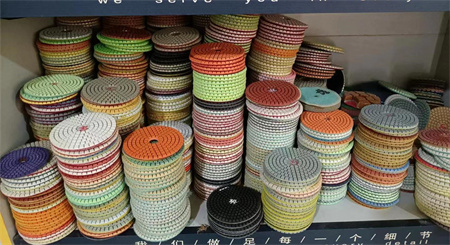

Once your stone is ready, the next step is choosing the right equipment. Polishing stones is not as simple as rubbing a cloth over the surface—high-quality, specialized tools are essential for a uniform result. Typically, this involves using a series of abrasives that progressively refine the stone, from coarse grinding discs to finer polishing pads. The key here is consistency. Using the same pressure and technique across the entire surface ensures an even polish, allowing you to gradually work out any imperfections.

To achieve symmetry, you must also be aware of the stone’s natural veining or grain patterns. These patterns can vary widely from one stone to another, and while they add character to the material, they can also create challenges when aiming for a perfectly even finish. In some cases, the natural lines of the stone may even be an asset, guiding your hand to polish in a specific direction. For stones with intricate veins, you’ll want to carefully follow the direction of the grain to ensure that the entire surface is polished with the same intensity, preventing any uneven spots or lines from emerging.

A vital aspect of symmetry in stone polishing is working in small, controlled sections. Rushing through a large surface area can lead to uneven pressure distribution, which in turn can affect the final result. Instead, take the time to focus on one area at a time, applying gentle but consistent pressure with each pass of your polishing pad. This technique helps to eliminate any variations in texture or glossiness that can disrupt the smoothness and symmetry of the stone’s surface.

When polishing large or complex stone pieces, such as countertops or flooring, using a polishing machine can save both time and energy. These machines are equipped with rotary or oscillating heads that help you maintain consistent pressure and motion across the surface. However, even with a machine, it’s crucial to monitor the process closely. Any deviation in angle or speed can cause uneven wear, leading to areas that are more polished than others. This is particularly true for stones with varying hardness, where a uniform approach will prevent certain sections from becoming over-polished.

Of course, no polishing job is complete without a final inspection. After you’ve polished the stone to your satisfaction, take a step back and examine the surface from different angles. This is your chance to spot any subtle irregularities that might have been missed during the process. If you notice any imperfections, go back with a finer abrasive or polishing pad and correct them. Symmetry isn’t just about uniformity in appearance—it’s also about consistency in texture and feel. The goal is a surface that is not only visually symmetrical but also smooth to the touch, creating an elegant, flawless finish.