Diamond Polishing Pads for Engineering Stone Industry

In the world of engineering stone, achieving the perfect finish is paramount. Whether you’re working with granite, marble, or quartz, the quality of the polish can make all the difference. That’s where diamond polishing pads come in. These essential tools are designed to provide exceptional results, turning rough, unfinished stone surfaces into smooth, lustrous finishes that are both aesthetically pleasing and durable.

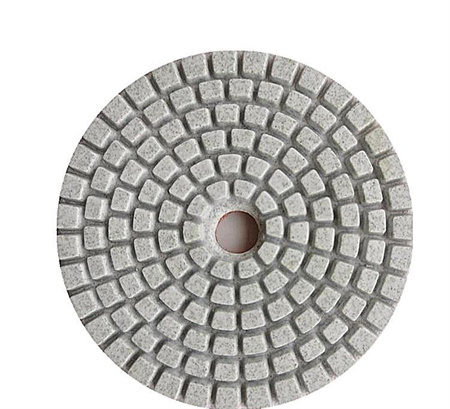

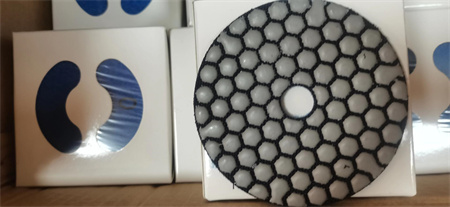

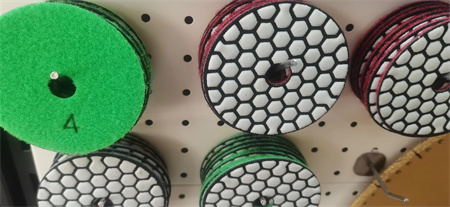

Diamond polishing pads are made with a combination of synthetic resin and industrial-grade diamonds, which makes them incredibly effective at grinding, smoothing, and polishing stone surfaces. Unlike traditional abrasives, diamond pads are known for their longevity and efficiency. The diamonds embedded in the pad work together to break down the stone gradually, leaving behind a flawless surface without causing excessive wear to the material.

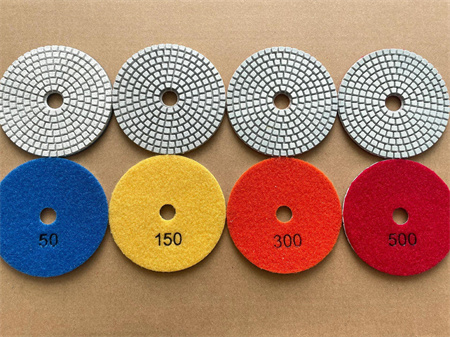

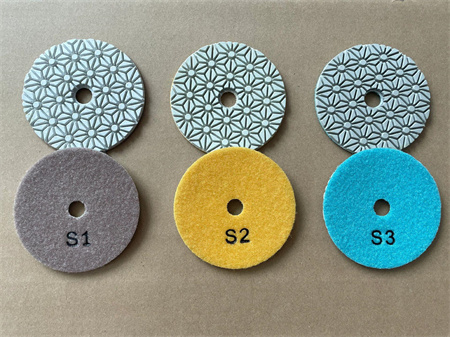

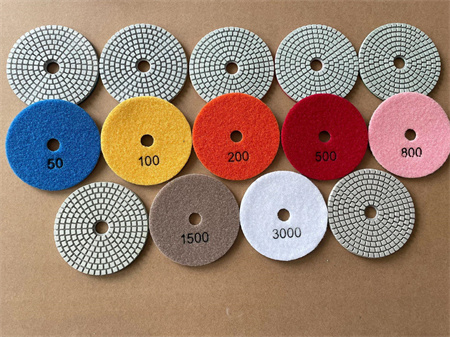

What sets diamond polishing pads apart is their versatility. They come in different grits, which means they can be used for everything from rough grinding to achieving a high-gloss finish. For engineering stone industries, this adaptability is key, as different stages of stone processing require different tools. By starting with a coarse grit and gradually moving to finer ones, professionals can achieve a consistent finish with minimal effort.

The benefits of using diamond polishing pads go beyond just the finish. These pads help to reduce labor time, improve efficiency, and enhance the overall quality of the stonework. They are designed to withstand high pressure and heat, making them ideal for heavy-duty applications in manufacturing plants and construction sites. Plus, the use of diamond-based technology means that even the toughest materials can be polished with ease, reducing the need for frequent replacements and downtime.

For the engineering stone industry, where precision and consistency are crucial, diamond polishing pads have become an indispensable tool. They help workers achieve that mirror-like shine that engineering stone is famous for while maintaining the structural integrity of the material. Whether it’s for countertops, flooring, or decorative elements, these pads ensure that the final product not only looks stunning but also stands the test of time.

As the engineering stone industry continues to grow, the demand for high-quality polishing tools will only increase. Diamond polishing pads, with their superior performance and reliability, will continue to play a central role in meeting this demand, allowing professionals to create flawless stone products that exceed expectations.