China Polishing Pad Manufacturer Bulk Exporter: Delivering Quality and Reliability

When it comes to polishing and buffing, every professional and business owner knows that the right tools are crucial to getting the perfect finish. Whether you’re in the automotive industry, working with furniture, or dealing with any other polishing needs, the quality of your polishing pads can make all the difference. And that’s where a trusted China polishing pad manufacturer bulk exporter steps in, offering both top-tier products and reliable service for clients around the world.

China has earned a reputation as a global hub for manufacturing, with an extensive range of products that cater to diverse industries. Among these, polishing pads stand out as essential components for anyone aiming for a spotless and smooth finish. As an expert in the field, a China-based manufacturer ensures that all pads meet the highest standards of durability, performance, and flexibility.

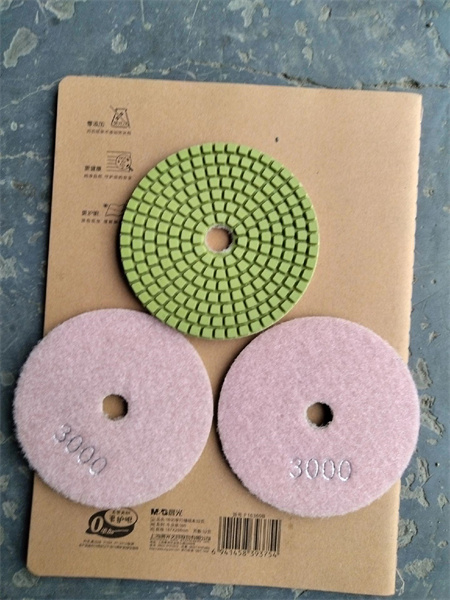

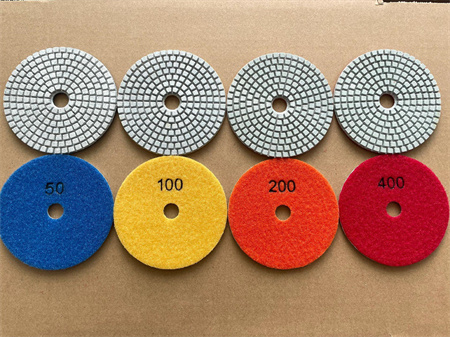

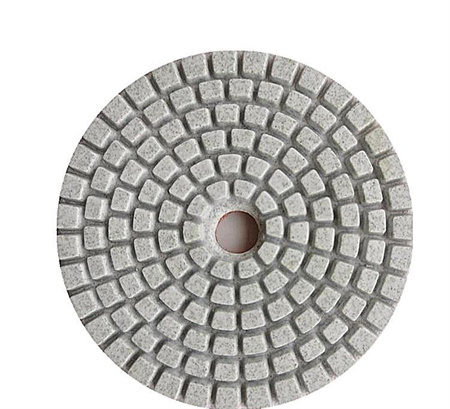

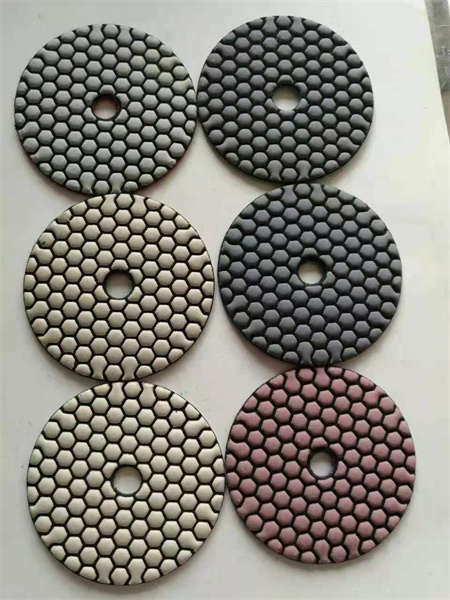

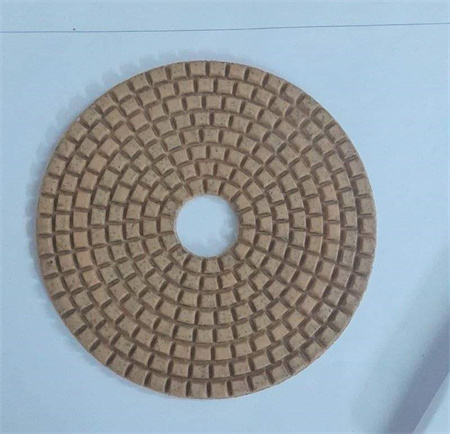

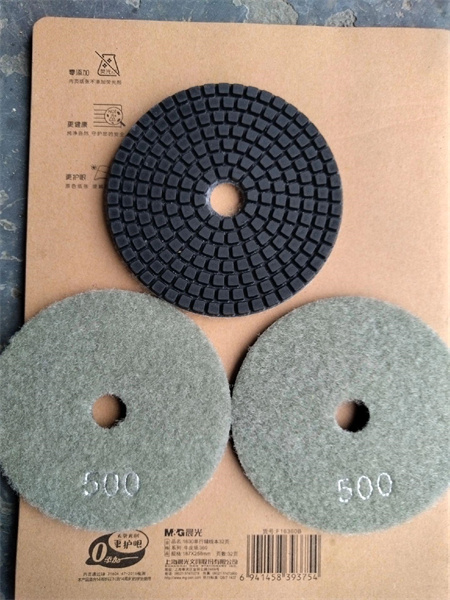

When you choose a reputable supplier, you can expect a wide variety of polishing pads tailored to different applications. From wool pads for heavy-duty tasks to foam pads that provide a more delicate touch, there’s something available for every polishing job. The materials used are not only effective but also eco-friendly, ensuring that your operations stay compliant with environmental standards. With advanced manufacturing processes, these pads are designed to handle different surfaces, from metal to plastic and beyond.

What sets a China polishing pad manufacturer apart is their ability to deliver in bulk, accommodating both large-scale operations and smaller businesses. Their bulk export capabilities mean that you don’t have to worry about frequent reorders, saving you both time and effort. With a streamlined supply chain, you can count on consistent product quality and timely deliveries, no matter where you are.

Trust and reliability are the cornerstones of any long-lasting business relationship, and that’s exactly what China polishing pad manufacturers offer. With decades of experience, they understand the complexities of different industries and ensure that their products perform at the highest level. Whether you’re looking for standard polishing pads or custom solutions tailored to your needs, a leading exporter has you covered.

Choosing a China-based manufacturer for your bulk polishing pad needs is an investment in quality, efficiency, and long-term satisfaction. With their products, you’re not just polishing surfaces — you’re polishing your business, ensuring that every project gets the attention it deserves. With the right polishing pads, the possibilities are endless!