When it comes to diamond polishing pads, finding the right balance between price and quality is crucial for anyone in the stone, marble, or concrete polishing industry. These tools, essential for achieving a high-quality finish on various surfaces, come in a wide range of prices, but does a higher price always guarantee better quality?

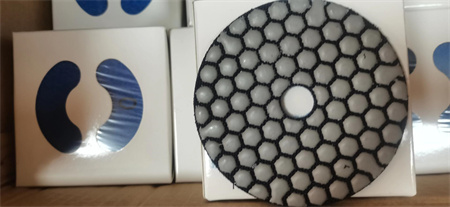

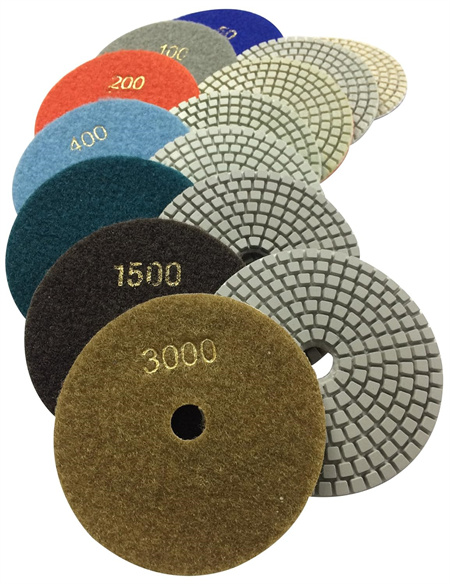

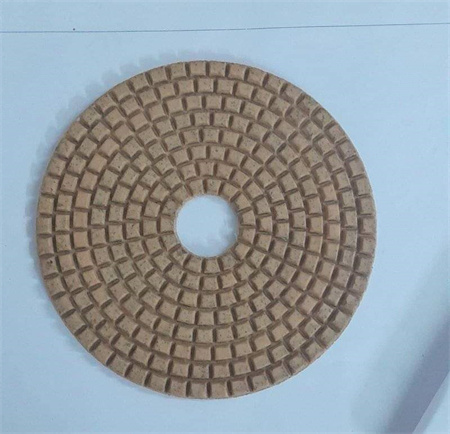

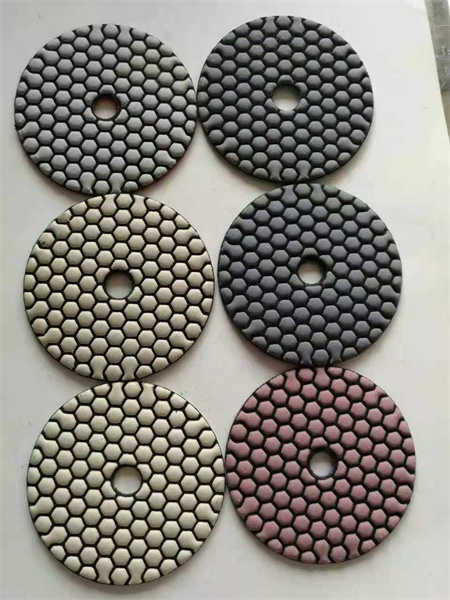

At the heart of this comparison lies the materials used. Diamond polishing pads are designed with industrial-grade diamonds embedded in the surface, allowing for efficient grinding and polishing. However, not all diamonds are created equal. High-quality pads typically feature more uniform diamond distribution and stronger bonds, leading to better performance and longer lifespan. This often reflects in the price. Pads with superior diamonds can last longer and deliver a smoother finish, making them a worthwhile investment for professionals who need consistent, reliable results.

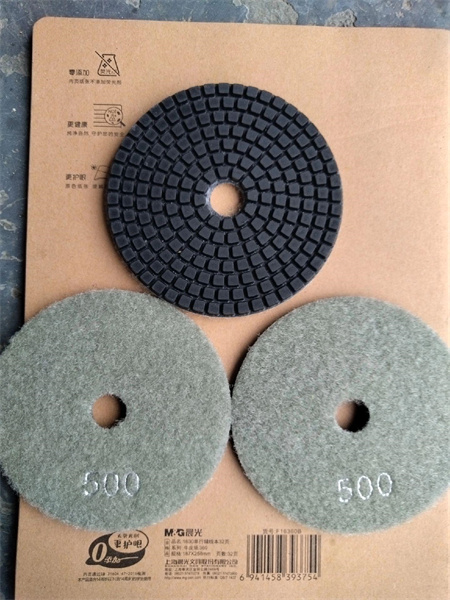

On the other hand, more affordable options may not have the same diamond density or durability. This can result in uneven finishes or a need for more frequent replacements. For hobbyists or those working on smaller projects, these lower-priced pads might be sufficient for the job, but they may not provide the same lasting results as their premium counterparts.

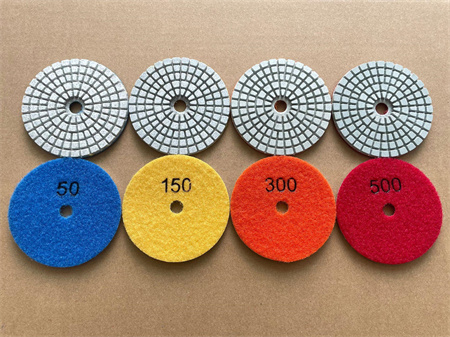

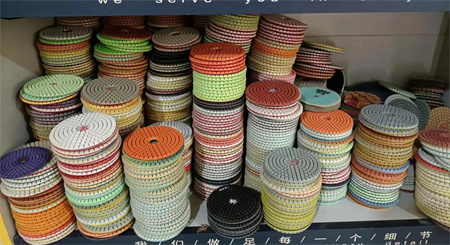

However, it’s not always about paying more for the best product. Some mid-range pads manage to strike a sweet spot between affordability and durability. They may not have the ultimate performance of high-end products but can still handle a variety of tasks with solid results. For businesses with budget constraints or those who use polishing pads in lower volumes, these pads can offer a reliable solution without the heavy investment of premium options.

The decision ultimately comes down to your specific needs. If you are a contractor working on large-scale, high-end projects, the investment in a high-quality, higher-priced pad might be worth it for the long-term savings and superior performance. For smaller, less frequent tasks, a budget-friendly alternative could do the job just fine. Regardless of the price point, ensuring that the pad is compatible with your equipment and that it delivers the finish you require is the key to making an informed purchase.

In the world of diamond polishing pads, price doesn’t always reflect the value for every user. Knowing your specific needs and understanding the trade-off between cost and durability will help you choose the right product for the job, making it a smarter, more economical purchase in the long run.