Looking for a reliable resin bond polishing pad manufacturer that guarantees fast delivery for importers? Look no further. Our company is committed to providing top-quality resin bond polishing pads that are designed to meet the needs of professionals in various industries, including stone, concrete, and floor care.

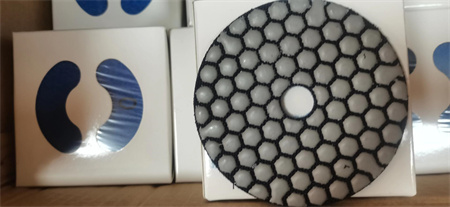

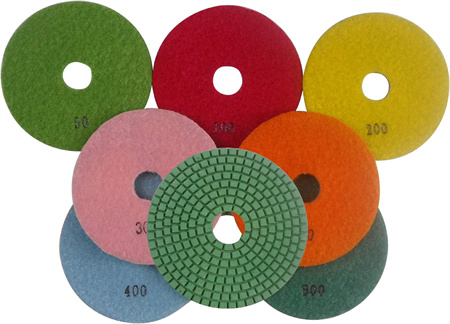

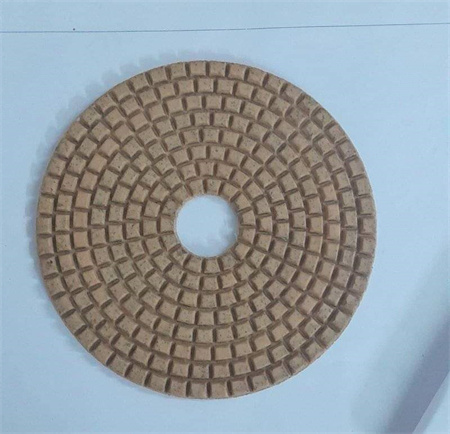

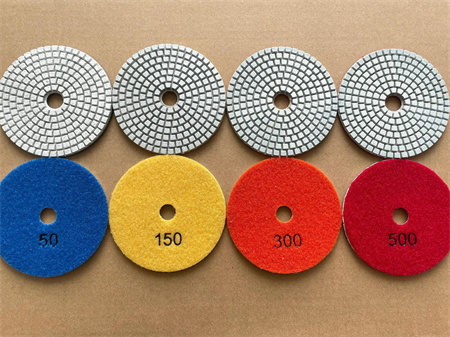

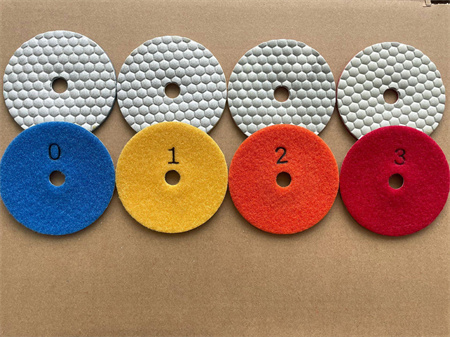

Resin bond polishing pads are highly sought after for their durability, flexibility, and superior finish. These pads are ideal for both wet and dry polishing, making them perfect for a wide range of applications. Whether you’re working with marble, granite, or other stone surfaces, our resin bond pads deliver the performance you expect, giving your surfaces a mirror-like finish with minimal effort.

We understand the importance of efficiency in the global market. That’s why we ensure quick turnaround times on all orders. As an importer, you can count on us for fast delivery, helping you meet your project deadlines and keep your business operations running smoothly. Our streamlined production process, combined with our extensive shipping network, allows us to ship products to international destinations without unnecessary delays.

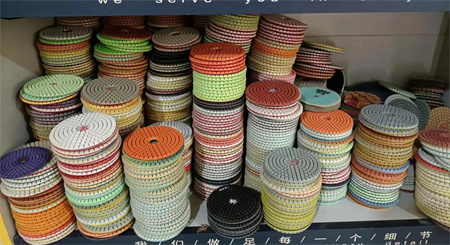

Our team of experts is dedicated to ensuring that every pad that leaves our facility meets the highest quality standards. We use only the best raw materials in the manufacturing process to ensure that our pads provide consistent results every time. Whether you’re polishing floors or countertops, our resin bond pads are engineered to stand up to the most demanding tasks.

Beyond quality and speed, we also offer flexible ordering options to suit the needs of our importers. Whether you require bulk orders or smaller quantities, we are here to accommodate your specific demands. Customization options are available for clients who need pads tailored to their particular specifications.

When you partner with us, you’re not just getting a product; you’re getting a reliable supplier who understands the value of time, quality, and service. Our resin bond polishing pads are crafted with precision, and we take pride in delivering the best products on time, every time.

So, if you’re looking for a resin bond polishing pad manufacturer who delivers on both quality and speed, contact us today. We look forward to helping you achieve the perfect finish on your projects while keeping your business operations on track.