Granite Polishing Tool OEM Manufacturer for Granite and Marble Workshops

When it comes to working with granite and marble, achieving a smooth and shiny finish is the ultimate goal. Whether you’re a small workshop or a large-scale operation, the right tools can make all the difference. If you’re looking to elevate your stone processing business, choosing the right granite polishing tools is a key factor. As an OEM (Original Equipment Manufacturer) for granite polishing tools, we specialize in providing custom solutions tailored to the specific needs of granite and marble workshops.

Polishing granite and marble isn’t just about the right techniques; it’s also about using the right tools. Our granite polishing tools are designed to provide an excellent finish, whether you’re working on small countertop pieces or larger slabs. These tools are built to handle the hardness and resilience of granite while delivering a smooth, glossy surface that’s highly valued in the industry. For workshops, investing in high-quality, durable polishing tools can save time and money in the long run.

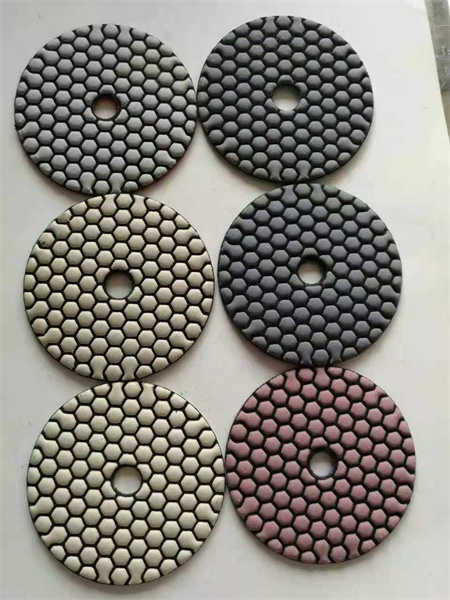

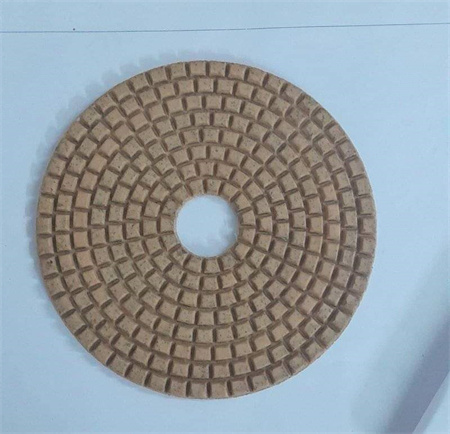

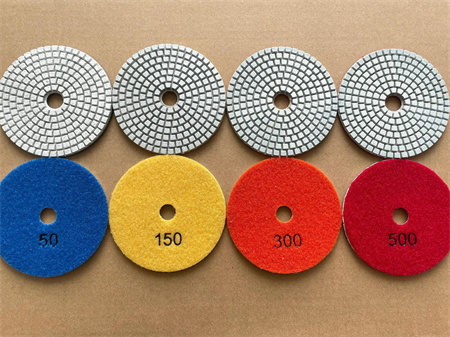

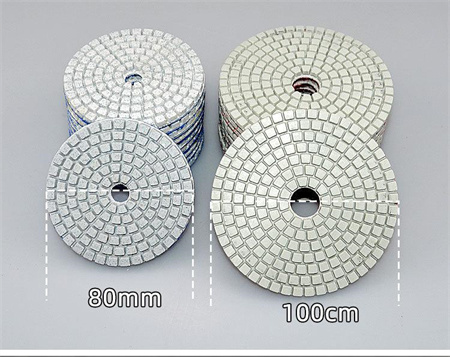

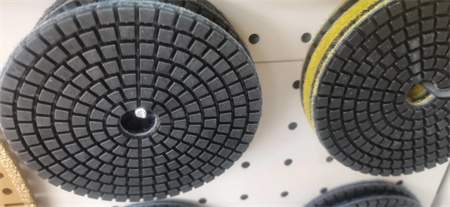

What sets us apart as an OEM manufacturer is our ability to produce granite polishing tools that cater to different workshop requirements. We understand that not all workshops are the same. Whether your team is polishing a variety of stone types or specializing in high-end marble countertops, we can customize tools to meet your needs. Our product range includes polishing pads, diamond polishing tools, and buffing wheels, all designed for efficiency and longevity.

Our commitment to quality ensures that each tool undergoes rigorous testing, ensuring long-lasting durability even under the most demanding conditions. When you use our granite polishing tools, you’re not just getting a product; you’re getting a reliable partner to help streamline your operations. With precision engineering, our tools provide consistent results, helping to reduce waste and increase productivity in the workshop.

Furthermore, we provide support and guidance to help you make the most out of your polishing tools. Our team of experts is available to offer advice on how to properly use and maintain your equipment to ensure peak performance. We also offer a wide range of accessories and consumables, so you can keep your workshop running smoothly without interruption.

In the competitive world of granite and marble, standing out means offering quality finishes. By partnering with an OEM manufacturer for granite polishing tools, you gain access to the best equipment that ensures your products are top-notch. No matter your workshop size or specific needs, we are here to help you achieve the polished, flawless results that keep customers coming back.