Diamond Polishing Pad OEM Exporter Factory China

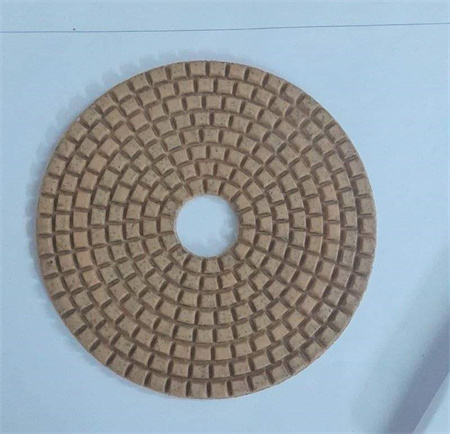

When it comes to high-quality diamond polishing pads, China has emerged as a leader in both production and innovation. As an OEM exporter, factories in China are known for providing durable, efficient, and cost-effective solutions for a wide range of industries, from construction and stone processing to automotive and electronics. These factories use state-of-the-art technology and a deep understanding of the market to meet the diverse needs of their clients worldwide.

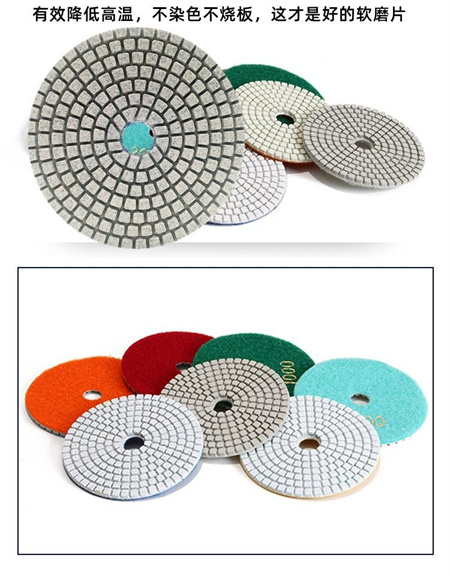

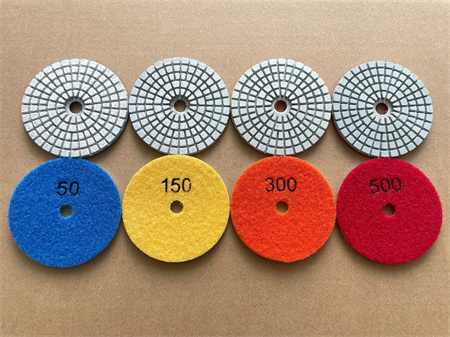

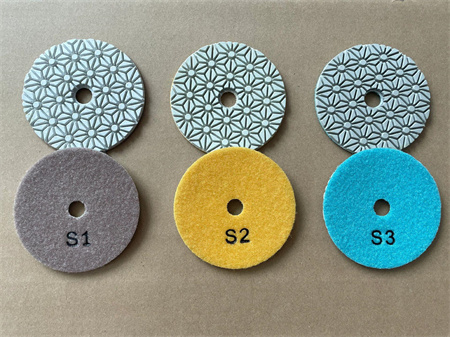

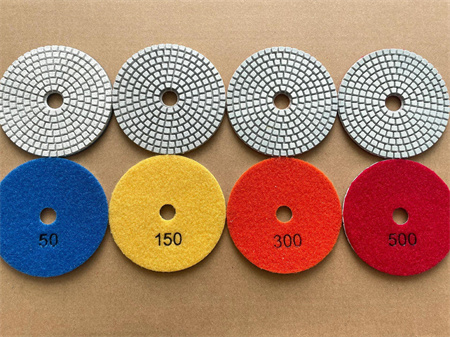

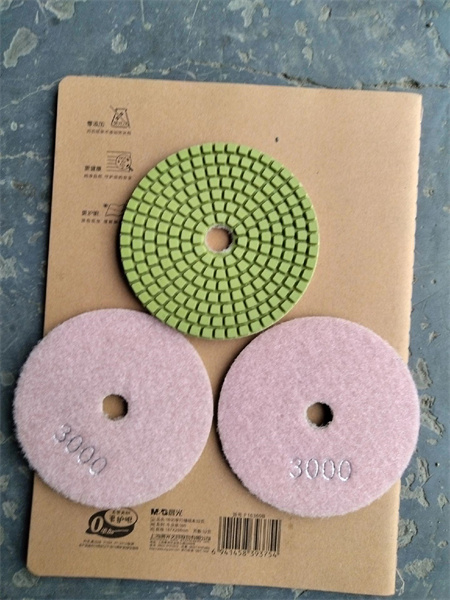

What sets Chinese manufacturers apart in the diamond polishing pad industry is their ability to offer customized solutions. OEM (Original Equipment Manufacturer) options allow clients to personalize products according to specific requirements, such as size, shape, grit level, and even the types of materials used in the manufacturing process. This flexibility ensures that customers can achieve the perfect polishing results for any project, whether it’s smoothing the surface of marble, granite, or even concrete.

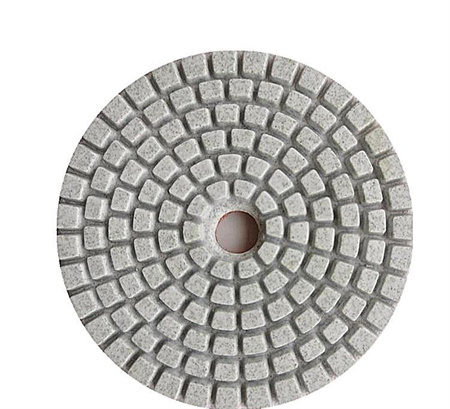

China’s export factories are known for their commitment to quality control. Each diamond polishing pad undergoes a rigorous inspection process to ensure it meets global standards. With advanced technology, Chinese manufacturers can produce pads that offer exceptional longevity, providing consistent performance even under heavy-duty conditions. Whether you’re polishing a small countertop or a large industrial floor, these pads are designed to provide a smooth, flawless finish every time.

Another key advantage of working with an OEM exporter in China is the competitive pricing. Thanks to efficient production processes and economies of scale, Chinese manufacturers can offer top-tier products at a fraction of the cost of many Western counterparts. This makes them an attractive option for businesses looking to save on production costs while still maintaining high standards of quality.

Furthermore, Chinese factories in the diamond polishing pad sector are known for their quick turnaround times. With the ability to handle both small and large orders, they can deliver products in a timely manner, ensuring that your project stays on track. The efficient supply chain and strong logistics networks in China also ensure that products can be shipped worldwide, reaching clients in a matter of days or weeks.

In conclusion, choosing a diamond polishing pad OEM exporter factory in China is a smart decision for businesses looking for high-quality, customizable, and cost-effective solutions. Whether you are in need of a specific type of polishing pad or require a high-volume order, Chinese manufacturers have the capacity, expertise, and competitive edge to meet your needs. The combination of quality, affordability, and timely delivery makes them the preferred choice for industries across the globe.