Granite Polishing Tool Made in China for Industrial Stone Importers

When it comes to achieving a high-quality finish for granite, one of the most important aspects is using the right tools. In the world of industrial stone importation, finding the best granite polishing tools can make a significant difference in both efficiency and the final product’s appearance. Fortunately, Chinese manufacturers have become a trusted source for innovative and affordable granite polishing tools that meet the needs of professionals worldwide.

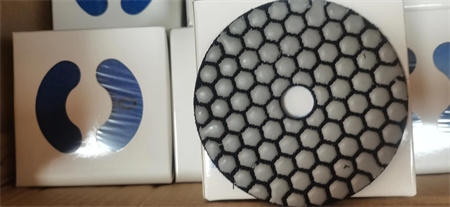

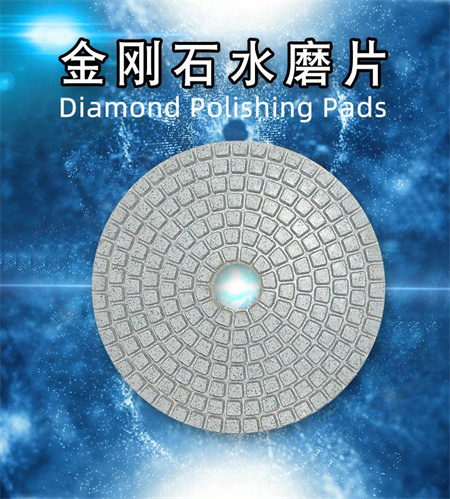

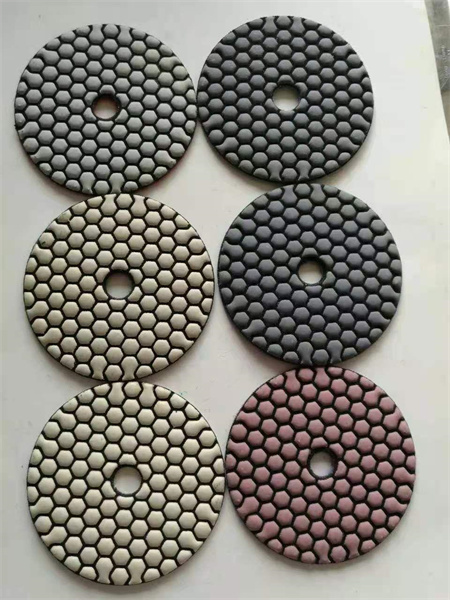

China has long been a leader in manufacturing tools for various industries, including the stone industry. With cutting-edge technology and skilled craftsmanship, Chinese manufacturers offer a wide range of granite polishing tools that cater to both large-scale operations and smaller businesses. These tools are specifically designed to provide precise, smooth, and glossy finishes on granite surfaces, making them a must-have for any industrial stone importer.

One of the reasons Chinese-made granite polishing tools are so popular among industrial stone importers is their durability. Whether you’re working with large slabs or small pieces, these tools are built to last. The high-quality materials used in the production process ensure that they can withstand the intense pressures and demands of the polishing process. Importers know that they can rely on these tools for consistent results, even after prolonged use.

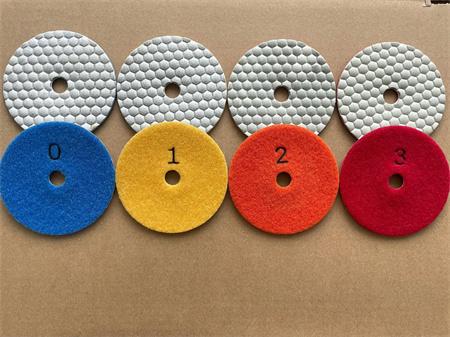

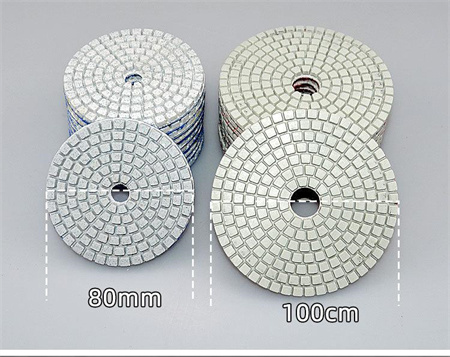

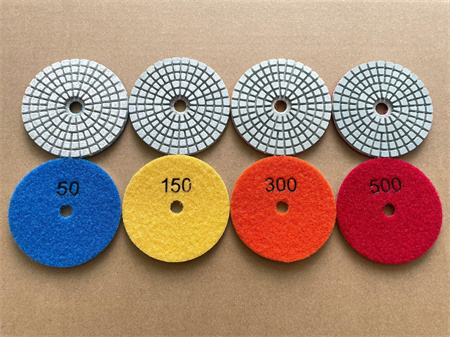

Another key advantage is the variety of options available. From handheld tools for small jobs to larger, more powerful machines for bigger projects, Chinese manufacturers offer a solution for every need. Many of these tools come with adjustable features, allowing users to control the speed and pressure, ensuring optimal results regardless of the type of granite being worked on. With such versatility, granite polishing becomes an easier, more efficient process.

Price is another factor that sets Chinese granite polishing tools apart. Due to the competitive manufacturing costs in China, these tools are often more affordable than those produced in other parts of the world. This makes them an attractive option for industrial stone importers who need to balance cost with performance. The quality-to-price ratio offered by Chinese manufacturers is hard to beat, making them a smart investment for businesses looking to enhance their stone processing operations.

For importers, establishing a relationship with trusted Chinese manufacturers can also mean access to excellent customer service. Many suppliers offer support, training, and after-sales services, ensuring that businesses can use their tools to their fullest potential. The level of commitment to customer satisfaction in the Chinese manufacturing sector has contributed to its widespread success in the global market.

In conclusion, granite polishing tools made in China are a game-changer for industrial stone importers. With their durability, variety, and affordability, they provide a practical solution for businesses aiming to enhance the quality of their stone products. As the demand for high-quality granite finishes continues to grow, these tools stand out as essential assets for stone professionals worldwide.