Title: China Diamond Polishing Pads Manufacturer Flexible Type

China has long been a leader in the manufacturing of various industrial products, and diamond polishing pads are no exception. Among these, the flexible type of diamond polishing pads has been gaining immense popularity due to its versatility and effectiveness in a wide range of applications. Whether you are working on natural stone, concrete, or other surfaces, a reliable manufacturer from China can provide high-quality pads that meet your polishing needs.

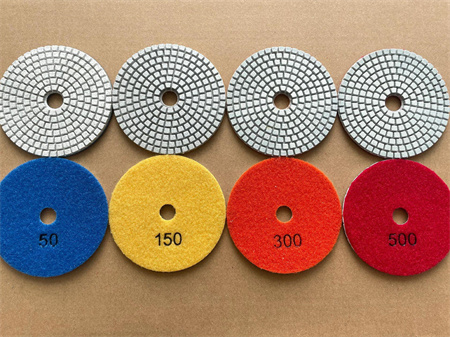

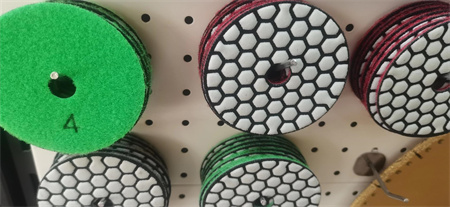

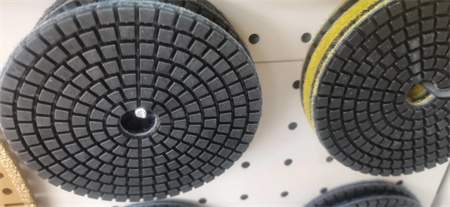

The flexible diamond polishing pads are designed to handle intricate surfaces with ease. They are perfect for achieving a smooth, glossy finish, making them an essential tool for professionals and DIY enthusiasts alike. These pads are commonly used in stone fabrication and restoration, offering excellent results on marble, granite, quartz, and other hard surfaces. Their flexibility allows them to conform to the contours of the surface, making them ideal for edge polishing or polishing surfaces with complex shapes.

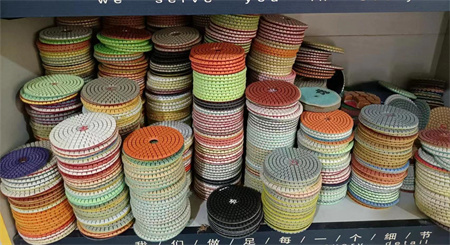

One of the main advantages of choosing a China-based manufacturer for diamond polishing pads is the cost-effectiveness without compromising quality. Chinese manufacturers often use advanced technology to produce durable and high-performing pads at a competitive price. This means businesses can source quality polishing pads in bulk without breaking the bank, while still ensuring the pads meet rigorous industry standards.

Durability is another significant benefit. A well-made diamond polishing pad from China is engineered to last longer than conventional pads, reducing the need for frequent replacements. The diamond particles embedded in the pad are of high quality, ensuring that the pad performs effectively for a longer period, even under heavy usage.

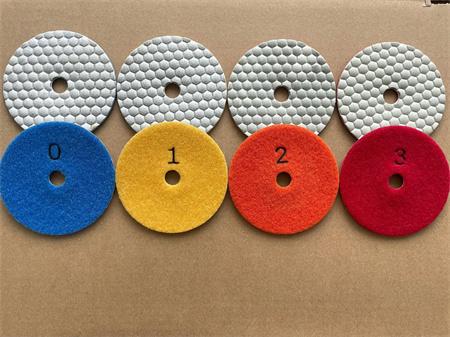

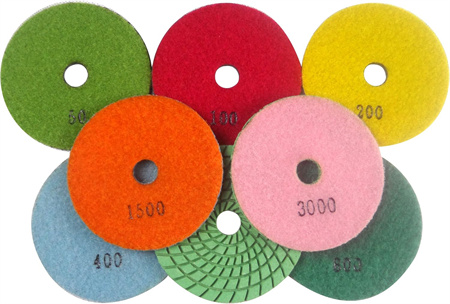

Moreover, manufacturers in China offer a range of options when it comes to the type of bond used in diamond pads. Whether you need a soft bond for softer materials or a hard bond for harder surfaces, there is a solution available to suit every polishing job. This flexibility makes it easier for users to select the right pad for their specific needs, resulting in better performance and a more efficient polishing process.

The rise of e-commerce and global shipping has made sourcing these polishing pads from China easier than ever. Many reputable manufacturers offer online catalogs, allowing customers to browse through their product ranges and place orders directly from their websites. With quick delivery and excellent customer service, it has never been more convenient to purchase high-quality diamond polishing pads.

Choosing a reliable China diamond polishing pads manufacturer for flexible types guarantees you are investing in top-tier products that will help you achieve professional-level results. Whether you’re working in a commercial setting or handling small personal projects, these pads are sure to enhance your polishing process, delivering precision and quality that speaks for itself.